Top 6 Logistics Management Software (LMS) features that you KNOW you need

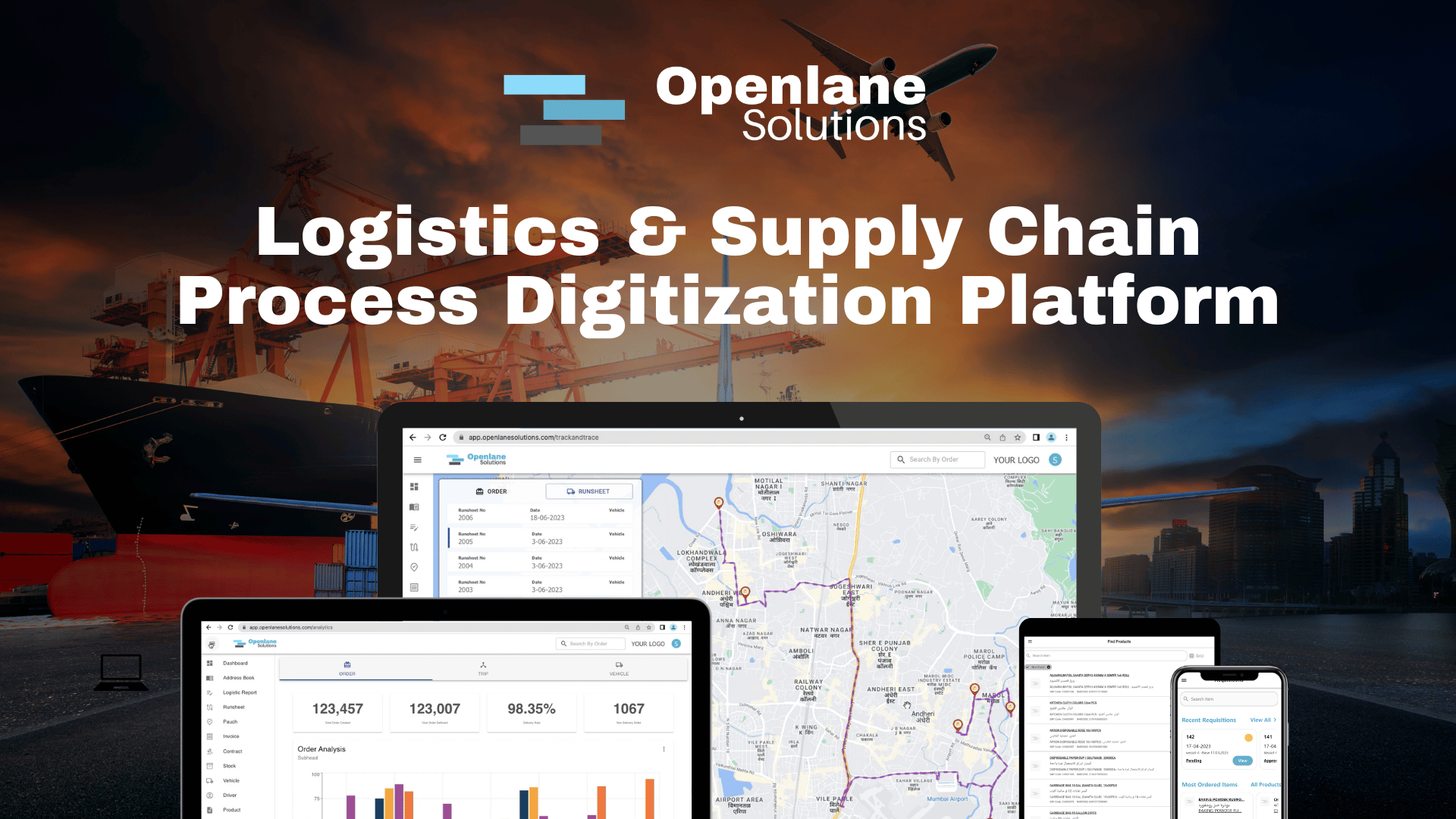

You know it. You need the most market-ready Logistics Management Software (LMS) that’s primed for your ground realities. Openlane’s LMS has the workflow and tools perfect for all users reflecting the needs of the drivers, handlers, managers, consigners, consignees, etc. The logistics management software seamlessly merges with all enterprise systems with zero data latency or...